The Digitisation Step SA Logistics Can’t Skip

A practical guide for cold chain operators navigating AI claims while building the foundations that make technology investment worthwhile

The previous ColdChainSA article on AI examined how to evaluate vendor claims—asking the right questions about training data, autonomous decisions, and demonstrated improvement over time. That article addressed the “should I believe this?” question.

This article tackles the follow-up question operators inevitably ask: “Okay, but how do I actually get there?”

The answer is less exciting than the marketing promises, but considerably more useful: before artificial intelligence can help your operations, you need operations that can be helped. The prerequisite isn’t sensors or data lakes—it’s process clarity.

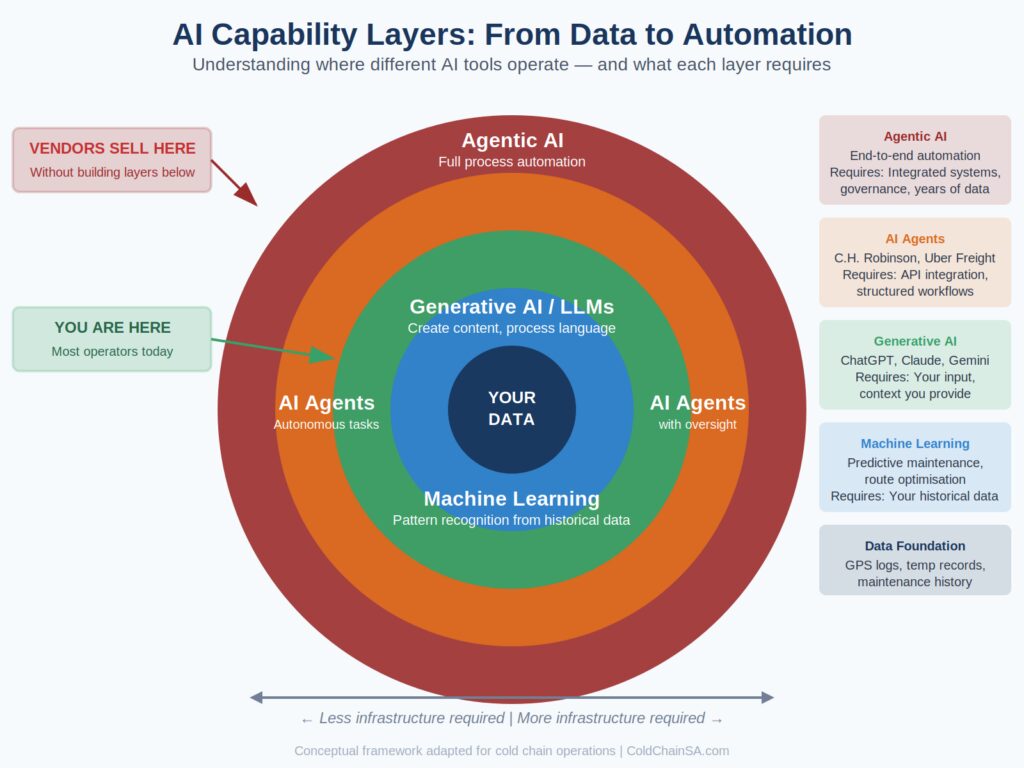

The AI Confusion: What Operators Actually Encounter

Walk into any logistics technology exhibition and you’ll hear “AI-powered” attached to everything from route planning software to temperature monitoring dashboards. The term has become so diluted that it obscures rather than clarifies what these tools actually do.

When an operator says “ChatGPT helped me draft that customer email” or “I used AI to summarise these compliance documents,” they’re using a specific technology: a Large Language Model. When a vendor promises “AI-driven route optimisation” or “predictive maintenance powered by artificial intelligence,” they’re describing something entirely different—systems that require sensor infrastructure, historical data, and integration pipelines that most operators don’t have.

This confusion isn’t academic. It shapes how operators allocate limited technology budgets and what expectations they carry into vendor conversations.

AI vs LLM: A Plain Language Distinction

- Artificial Intelligence is the umbrella concept—machines performing tasks that typically require human intelligence. It’s the goal, not the method.

- Machine Learning is one approach to achieving AI—algorithms that improve through exposure to data rather than explicit programming. Instead of coding “if temperature exceeds 5°C, send alert,” you feed the system thousands of examples and it learns the pattern. This requires substantial historical data with known outcomes: equipment that failed and equipment that didn’t, deliveries that spoiled and deliveries that arrived intact.

- Large Language Models are a specific type of machine learning system trained on massive text datasets to understand and generate language. They predict statistically likely responses based on patterns in their training data. ChatGPT, Claude, and similar tools are LLMs.

This framework is adapted from AI capability concepts shared by Luis F. Rodrigues on LinkedIn.

Why this matters

When you use ChatGPT to help write a standard operating procedure, you’re leveraging an LLM. It processes your description of the workflow and generates structured documentation because it recognises patterns in how procedures are typically written. It doesn’t understand refrigeration physics or your specific operational constraints—it understands language patterns.

When a vendor sells “AI-powered route optimisation,” they’re (supposedly) using machine learning trained on historical route data, traffic patterns, delivery windows, and fuel consumption. This requires your data, collected over months or years, with outcomes measured consistently.

The operator who thinks “ChatGPT helps me, so AI can transform my fleet” is conflating a language tool with a data-driven operational system. They require entirely different prerequisites.

Where South African Logistics Actually Operates

The AI marketing materials assume a specific operational context: integrated systems, structured data, consistent connectivity, and documented processes. This describes some large European distribution networks. It does not describe the typical South African cold chain operation.

WhatsApp as the Operating System

Here’s what the technology vendors don’t acknowledge: a significant portion of South African logistics runs on WhatsApp.

Not as a backup communication channel. Not as a supplement to formal booking systems. As the primary coordination mechanism.

A refrigerated transport operation might have one WhatsApp group per major customer. Booking requests come in as voice notes or text messages. Load confirmations happen via reply. Delivery updates, route changes, capacity queries, driver instructions—all flowing through informal chat channels that leave no structured data trail.

This isn’t a problem to be fixed. It’s the reality to work with.

WhatsApp dominates because it works. It’s free. Everyone already has it. Voice notes overcome literacy barriers. Group chats create transparency. Read receipts confirm receipt. It requires no training, no implementation project, no IT support.

The dispatcher coordinating a fleet through multiple WhatsApp groups is performing genuine operational intelligence—interpreting requests, matching capacity, managing exceptions, maintaining relationships. The information processing happens in their head, not in a system.

The Tacit Knowledge Problem

When that dispatcher goes on leave, what happens? Someone else takes over the phone, reads through the chat histories, and tries to reconstruct the context. Customer preferences, driver capabilities, route complications, historical issues—all stored in human memory rather than documented systems.

This tacit knowledge represents both operational value and organisational risk. The experienced dispatcher who knows which customer’s loading bay adds 30 minutes to every delivery possesses information no AI system can access. But if that knowledge isn’t captured somewhere, it walks out the door with the employee.

AI vendors promise to extract insights from your operational data. But when your operational data consists of WhatsApp voice notes and an experienced person’s institutional memory, there’s nothing for AI to analyse.

The Missing Middle Step

Technology vendors sell a compelling vision: implement their AI solution and transform your operations. The marketing shows seamless dashboards, automated decisions, efficiency gains measured in percentages.

What they skip is the middle step—the unglamorous work that makes any of this possible.

The honest sequence looks like this:

- Manual operations — Paper-based or informal digital (WhatsApp, email), knowledge lives in people’s heads, processes vary by who’s working that day

- Digitised operations with defined rules — Documented workflows, explicit decision logic, consistent data capture, systems that enforce process consistency

- AI-augmented operations — Technology that learns from your documented processes and historical data to improve efficiency, predict issues, or automate routine decisions

Most operators are at stage 1. Vendors want to sell stage 3 solutions. Stage 2 is where the actual work lives—and nobody wants to pay for it.

What Digitisation Actually Requires

Moving from informal to documented operations isn’t a technology purchase. It’s organisational work that happens to use technology.

Documenting actual workflows

Not the idealised process that exists in someone’s head. The real one—including the workarounds, exceptions, and “we’ve always done it this way” practices that make things actually function.

When the experienced dispatcher receives a booking request, what happens? They read the message, identify the customer, recall their typical requirements, check mental inventory of available vehicles, consider driver locations and capabilities, assess timing against other commitments, and reply with a confirmation or counter-proposal.

That entire decision tree lives in wetware. Documenting it requires asking questions most operators have never formalised: How do you decide which truck gets which load? What makes a delivery urgent versus routine? When do you say no to a booking? What triggers you to escalate a problem?

Defining decision rules explicitly

Once you understand how decisions actually get made, you can express them as logic. If the load requires frozen, and Vehicle 3 is the only frozen-capable unit available, and the delivery window conflicts with Vehicle 3’s current assignment, then [what?].

Most operators cannot fully articulate their decision rules because too much is intuitive. The dispatcher “just knows” that Customer X’s loads always require extra time, or that Driver Y handles difficult routes better than Driver Z. That knowledge is valuable. It’s also invisible to any system.

Identifying exceptions and how they’re handled

Real operations are messy. The documented process says one thing; reality does another. Good process documentation captures not just the standard path but the common exceptions and how they’re resolved.

What happens when a vehicle breaks down mid-route? When a customer changes delivery time at the last minute? When load shedding hits the cold store? These exception-handling procedures are often where operational expertise truly lives—and where documentation is most lacking.

The Honest Question

Can you write down your decision rules? Most operators can’t fully—too much tacit knowledge.

Can those rules run in a basic system without AI? A spreadsheet, a simple app, whatever enforces consistency?

Only then does the question become: can AI reduce friction at the input/output layers?

If your business runs on experience and intuition (which works), AI has nothing to grab onto. You’ve got skilled people doing skilled work. Technology can support them, but it can’t replicate judgment it cannot access.

Tools for Process Documentation

Operators interested in formalising their workflows don’t need enterprise software. They need tools that are simple enough to use, powerful enough to capture real complexity, and capable of producing outputs that systems can eventually consume.

The goal isn’t perfection. It’s moving from “the process lives in Themba’s head” to “the process is written down somewhere we can reference and improve.”

| Tool Category | Examples | What It Produces | Cost Range |

|---|---|---|---|

| Flowchart and process mapping | Lucidchart, Miro, Draw.io | Visual diagrams, some export to XML/JSON | Free tiers available; paid from R150/month |

| Business process modelling | Camunda Modeler, Bizagi Modeler | BPMN files (standardised, machine-readable) | Free for basic modelling |

| No-code workflow builders | n8n, Make (Integromat), Zapier | Executable workflows, API integrations | Free tiers available; paid scales with usage |

| Structured documentation | Notion, Coda, Airtable | Databases behind documents | Free tiers available; paid from R100/month |

| Simple documentation | Google Docs, Microsoft Word | Text documents, can include diagrams | Often already available |

The gap to understand

Most process documentation tools are designed for humans to read. Most automation systems expect structured data as input. The bridge between “dispatcher knowledge written down” and “system can act on this” is where projects stall.

Starting with documentation in any format beats having nothing documented. But if eventual system integration matters, choosing tools that produce structured outputs (like BPMN-format files) provides a better foundation than pure prose documentation.

The realistic path

Start with whatever tool your team will actually use. A Google Doc describing the booking process is infinitely more valuable than a sophisticated BPMN diagram nobody creates. Once documentation exists, it can be migrated to more structured formats.

Understanding the Tools: What’s on Your Phone vs What Vendors Sell

Operators increasingly encounter AI tools in daily life—ChatGPT, Gemini, Claude—often on their phones. Meanwhile, vendors sell “AI-powered logistics solutions” that sound similar but operate entirely differently. Understanding this distinction prevents confusion about what’s achievable with each.

The LLM Tools You Already Have Access To

These are the consumer-facing AI assistants available via app or browser. They’re all Large Language Models—trained on massive text datasets to understand and generate language. The differences lie in training approach, interface design, and what they’re optimised for.

| Tool | Provider | Training Approach | Best For | Access |

|---|---|---|---|---|

| ChatGPT | OpenAI | Trained on broad internet text, optimised for conversation | General drafting, brainstorming, quick answers | Free tier + paid (R350/month) |

| Claude | Anthropic | Trained with emphasis on helpfulness and safety, strong at long documents | Document review, research synthesis, nuanced writing | Free tier + paid |

| Gemini | Integrated with Google services, multimodal (text + images) | Users in Google ecosystem, image analysis | Free with Google account | |

| Copilot | Microsoft | OpenAI models integrated into Microsoft 365 | Users in Microsoft ecosystem, Office document work | Included with Microsoft 365 |

| Grok | xAI | Real-time access to X/Twitter data | Current events, social media context | X Premium subscription |

| DeepSeek | DeepSeek | Open-weight model, strong reasoning | Technical analysis, cost-conscious users | Free |

| Perplexity | Multiple models | Optimised for search with citations | Research requiring source verification | Free tier + paid |

| Julius | Specialised | Focused on data analysis | Spreadsheet work, charts, numerical analysis | Free tier + paid |

The key insight

These tools all do fundamentally the same thing—process language. ChatGPT and Claude and Gemini are not competing logistics platforms. They’re different interfaces to similar underlying technology, each with different strengths based on how they were trained and what integrations they offer.

When you ask ChatGPT to “draft a customer apology for a delayed delivery,” it generates text based on patterns in how apology letters are typically written. It doesn’t know your customer, your delivery history, or your company policies. You provide that context; it provides language structuring.

Why training matters

Remember the earlier point about AI needing data? These consumer LLMs were trained on internet-scale text data—billions of documents, websites, books. That’s why they can write coherently about almost any topic.

But they weren’t trained on your operational data. They don’t know your routes, your customers, your equipment, your procedures. They can help you articulate what you already know. They can’t make operational decisions they have no information about.

This is the fundamental difference between “ChatGPT helped me write that email” and “AI optimised my route planning.” The first uses a general language model. The second requires a system trained on your specific operational history.

Logistics-Specific AI Platforms

At the other end of the spectrum sit enterprise platforms built specifically for logistics operations. These aren’t language models—they’re operational systems that incorporate various AI techniques (machine learning, computer vision, predictive analytics) for specific functions.

Global platforms (primarily enterprise-scale):

- Project44 / FourKites — Real-time visibility platforms using predictive analytics for arrival estimates and disruption alerts

- C.H. Robinson’s Navisphere — Uses 30+ AI agents processing millions of shipment tasks, trained on 37 million annual shipments

- Flexport — Digital forwarding platform combining software with AI for routing and inventory positioning

- Oracle / SAP Logistics — Enterprise transportation management with AI embedded for demand forecasting and route optimisation

South African market options:

- Cartrack — Fleet management with AI-powered cameras for driver behaviour, trained on local driving patterns

- MiX by Powerfleet — Telematics with MiX Vision AI for safety monitoring and predictive maintenance

- Webfleet (Bridgestone) — Fleet Advisor using generative AI for fleet insights, local support

- Tracker SA / Geotab — Vehicle tracking with analytics capabilities

The critical difference:

These platforms are built on operational data integration—GPS feeds, sensor data, transaction histories, delivery outcomes. The AI components work because they’re connected to structured data sources.

When C.H. Robinson’s AI processes quote requests, it’s drawing on decades of shipment data to predict pricing. When Cartrack’s AI camera detects driver fatigue, it’s using computer vision trained on thousands of examples of drowsy driving behaviour.

You can’t replicate this by typing into ChatGPT. These are different categories of tool entirely.

Where Consumer LLMs and Logistics Operations Intersect

The practical question: how can operators use the tools they already have access to?

Consumer LLMs help with the language layer of operations—not the operational decisions themselves.

Realistic applications:

- Drafting customer communications (delays, apologies, confirmations)

- Summarising regulatory documents into actionable checklists

- Converting rough notes into structured procedures

- Translating technical specifications into plain language

- Preparing tender responses and proposal documents

- Creating training materials from operational knowledge

Not realistic applications:

- Route optimisation (requires your route data, which ChatGPT doesn’t have)

- Predictive maintenance (requires sensor data and failure history)

- Demand forecasting (requires sales data and customer patterns)

- Real-time dispatch decisions (requires current vehicle positions and availability)

The gap between these categories is precisely the “missing middle step” discussed earlier. Consumer LLMs can help you document and communicate. Operational AI requires the infrastructure you haven’t built yet.

Where LLMs Genuinely Add Value Today

While the “AI transformation” promises require infrastructure most operators lack, Large Language Models offer practical value right now—if expectations are calibrated correctly.

Communication Parsing and Structuring

LLMs excel at processing unstructured text. A WhatsApp message reading “hi need frozen truck for tomorrow morning joburg to durban 8 pallets” contains booking information that a human dispatcher extracts instantly. An LLM could extract the same structured data: temperature requirement (frozen), date (tomorrow), origin (Johannesburg), destination (Durban), volume (8 pallets).

This doesn’t require your historical data. It requires access to the message stream and a system to receive the structured output.

The practical application:

An LLM-based solution could monitor WhatsApp Business conversations and extract booking requests into a structured format—populating fields in a spreadsheet or simple booking system. The dispatcher still makes decisions. The LLM handles the translation from informal communication to structured data.

What this requires:

- WhatsApp Business API integration (available through providers like Clickatell, CM.com, or Cellfind, typically starting around R600/month plus per-message costs)

- LLM API access (OpenAI, Anthropic, or similar)

- Custom development connecting the pieces

- Your operational rules codified (what fields matter, what defaults apply, what triggers escalation)

- Human oversight (dispatcher reviews and approves, not blind automation)

This is buildable today. It’s not science fiction. But it’s also not “plug in ChatGPT and go.” It’s a custom software project requiring development expertise and your operational knowledge formalised into rules.

Articulation and Synthesis Support

The value in the working relationship between an operator and an LLM tool often isn’t that the AI knows logistics—it’s that the AI helps structure and express what the operator already knows.

Draft a standard operating procedure by describing the workflow conversationally, and the LLM produces structured documentation. Summarise a complex compliance document into actionable requirements. Convert technical specifications into customer-friendly explanations. Translate rough meeting notes into coherent action items.

This articulation support is available now, requires no integration, and delivers immediate value. The operator provides domain expertise; the LLM provides language structuring.

The honest framing:

These tools help operators work more efficiently with information. They don’t replace operational knowledge. They don’t learn your business over time (unless specifically built to do so). They don’t make decisions.

When someone says “I couldn’t run my business without ChatGPT,” they usually mean “ChatGPT helps me communicate and document faster.” That’s genuinely valuable. It’s also different from AI transforming logistics operations.

Document Processing and Compliance Support

Regulatory documents, equipment manuals, certification requirements—cold chain operations generate substantial documentation that someone needs to read, understand, and act on.

LLMs can summarise long documents into key requirements. They can compare your current procedures against regulatory standards and flag gaps. They can translate technical specifications into implementation checklists.

This is language processing, not logistics intelligence. The LLM doesn’t know whether your procedures actually achieve compliance—it can identify whether your documented procedures address the topics a regulation requires.

Practical applications:

- Summarising new R638 amendments into operational impact summary

- Reviewing equipment specifications against tender requirements

- Converting audit findings into action item lists

- Drafting customer-facing explanations of your compliance certifications

What the Marketing Calls “AI” Still Requires

The previous ColdChainSA article detailed the prerequisites for genuine AI value—abundant historical data, clear success metrics, consistent data formats. Those requirements haven’t changed.

But it’s worth revisiting what the high-value applications actually demand, because vendors often present them as turnkey solutions when they’re anything but.

Route Optimisation

What the marketing says: AI analyses your routes and identifies efficiency improvements, reducing fuel costs and improving delivery windows.

What it actually requires:

- GPS tracking data covering 12-18 months minimum (to capture seasonal patterns)

- Consistent route coverage (the system can’t optimise routes it’s never seen)

- Integration with delivery scheduling systems

- Clear optimisation objectives you’ve defined (minimise fuel? minimise time? maximise deliveries? balance all three?)

- Historical outcome data (which routes actually delivered on time, which had issues)

The realistic assessment:

Large fleets running consistent territories with years of GPS data can achieve meaningful route optimisation gains. A smaller operator running variable routes with limited tracking history may find that driver experience, basic mapping tools, and scheduled departure windows deliver most of the achievable benefit.

Predictive Maintenance

What the marketing says: AI monitors your equipment and predicts failures before they occur, preventing costly breakdowns and load losses.

What it actually requires:

- Continuous sensor data from refrigeration equipment—not just temperature, but compressor cycling, power consumption, condenser temperatures, vibration patterns

- Historical data spanning multiple actual failures (you can’t train a failure prediction model without failure data)

- Consistent equipment types (a model trained on one compressor brand may not generalise)

- Integration with maintenance management systems to action predictions

- Sufficient fleet scale to accumulate meaningful failure data in reasonable timeframes

The realistic assessment:

An operator with 200 refrigeration units accumulates meaningful failure data over a few years. An operator with 20 units may wait years between compressor failures—not enough events to train reliable predictions.

Scheduled preventive maintenance based on manufacturer recommendations and operating hours often delivers similar outcomes without AI complexity.

The Pattern

Notice what all these applications have in common: they require infrastructure that exists independently of the AI system. GPS tracking must already be in place. Sensor data must already be flowing. Maintenance records must already be structured.

AI analyses existing data. It doesn’t create the data collection infrastructure. Vendors who promise AI transformation without first asking about your data infrastructure either don’t understand the technology or hope you don’t.

The Honest Path Forward

Technology will eventually transform cold chain operations. The question isn’t whether to engage with AI, but how to sequence investments so they deliver value rather than expensive disappointment.

Step One: Document What You Actually Do

Before any technology investment, capture your current operations in written form. This doesn’t require software—it requires discipline.

For each major process (booking, dispatch, delivery, maintenance, customer communication):

- Who does what, in what sequence?

- What information do they need to make decisions?

- What triggers exceptions or escalations?

- Where does information currently live (WhatsApp, spreadsheet, paper, someone’s memory)?

- What goes wrong, and how is it fixed?

This documentation serves multiple purposes. It creates organisational knowledge that survives personnel changes. It identifies inefficiencies visible only when written down. It provides the foundation for any future system implementation.

The realistic commitment:

This takes time. A thorough process documentation exercise might require 20-40 hours of work for a small operation—interviews with key staff, observation of actual workflows, drafting and revision.

Most operators won’t do this because it doesn’t feel urgent and doesn’t generate immediate return. That’s precisely why competitors who do it gain advantage.

Step Two: Digitise Data Capture Points

Once processes are documented, identify where information enters the operation and ensure it gets captured in accessible form.

- Booking requests: Can these flow into a spreadsheet or simple system rather than remaining only in WhatsApp history?

- Temperature records: Are these downloading regularly from data loggers, or sitting on USB drives until audit time?

- Delivery confirmations: Is there a consistent record of what was delivered when, or does this live in driver memory and occasional photos?

- Maintenance events: When equipment gets serviced, is this logged consistently?

The goal isn’t sophistication. It’s consistency. A Google Sheets workbook that every booking passes through creates more analytical value than sophisticated software nobody uses.

Step Three: Build Decision Consistency

With processes documented and data capturing, establish consistent decision frameworks. Not AI-driven automation—human decision-making supported by explicit criteria.

When a booking request arrives, what questions must be answered before confirming? When temperature excursion occurs, what’s the response procedure? When equipment shows warning signs, what triggers maintenance scheduling?

These don’t need to be rigid rules. They can be checklists, decision trees, or reference guidelines. The point is moving from “the experienced person just knows” to “anyone following this procedure would reach a similar conclusion.”

Step Four: Then Evaluate AI Tools

Only after steps 1-3 deliver value does AI investment make sense. At that point, you have:

- Documented processes that technology can support (not replace)

- Historical data that ML systems can learn from

- Explicit decision criteria that automation can implement

- Clear understanding of where efficiency gains are possible

Now vendor conversations become productive. You can ask: “Given that I have 18 months of GPS data in this format, what route optimisation is achievable?” rather than “Can AI transform my logistics?”

What ColdChainSA Is Doing

At The Frozen Food Courier, the operation behind ColdChainSA, we’re starting the process documentation work ourselves. Not because we’ve solved these challenges—because we face them like every other operator.

We’ll document what we learn. Where tools prove useful, we’ll share that experience. Where approaches fail, we’ll be honest about why.

The goal isn’t to become a technology company. It’s to build the operational foundations that make future technology investment worthwhile—and to share that journey with operators facing similar decisions.

The Bottom Line

AI will transform cold chain logistics. The technologies are real, the applications are genuine, and operators who build appropriate capabilities will capture competitive advantage.

But the sequence matters. Process documentation before technology investment. Data infrastructure before AI implementation. Realistic assessment of prerequisites before vendor commitment.

The operators who thrive won’t necessarily be the earliest AI adopters. They’ll be the operators who build solid operational foundations—documented processes, consistent data capture, explicit decision frameworks—that make technology investment worthwhile whenever they choose to pursue it.

Sometimes the most valuable technology investment is the boring work of writing down how your business actually operates. That foundation makes everything else possible.

Sources and References

About These Sources

This article draws on academic research, technology provider documentation, and industry analysis focused on LLM applications in logistics and business process management. South African market context reflects publicly available information from local technology providers and SME-focused publications. All sources were verified as of January 2026.

Citation Methodology

Technical claims about LLM capabilities reference academic and industry research. WhatsApp Business API information reflects current South African provider offerings. Process documentation tool categories represent established software categories with examples from major providers. Where analysis extends beyond published sources, the article indicates operational experience and industry observation.

AI and LLM Technology Fundamentals

- International Journal of Computer Trends and Technology: Leveraging LLMs in Logistics Tech (2025) — Academic research examining how Large Language Models deliver real-time freight visibility, document processing, and communication automation in logistics operations.

- ScienceDirect: Exploring the Roles of Large Language Models in Reshaping Transportation Systems (2025) — Comprehensive survey presenting a framework for LLM applications in transportation across information processing, knowledge encoding, and decision facilitation.

- Taylor & Francis: Agentic LLMs in the Supply Chain (2025) — Research on how LLM agents can automate consensus-seeking in supply chains, demonstrating practical applications in inventory management and coordination.

- Sebastian Raschka: The State of LLMs 2025 — Comprehensive technical analysis of LLM developments including reasoning models, open-weight alternatives, and practical deployment considerations.

- Simon Willison: 2025 – The Year in LLMs — Industry practitioner analysis of LLM developments including agent capabilities, coding applications, and practical deployment patterns.

Logistics AI Platforms and Enterprise Solutions

- Tank Transport: Top 5 Breakthroughs in AI in Freight Brokerage (2025) — Analysis of enterprise AI implementations including C.H. Robinson’s 30+ AI agents processing 3 million shipment tasks and Uber Freight’s Insights AI platform.

- Transport Topics: Putting AI to Work in Trucking (2025) — Industry analysis of practical AI implementations across motor carriers, freight brokers, and shippers, including data quality requirements and integration challenges.

- Wisor: 10 Best AI Tools for Freight Forwarders (2025) — Overview of AI-enabled platforms for freight operations including FourKites, Project44, Flexport, and Shipwell with focus on practical implementation requirements.

- AIMultiple Research: Top 15 Logistics AI Use Cases (2026) — Comprehensive analysis of AI applications in logistics including chatbots, route optimisation, predictive maintenance, and warehouse automation with implementation considerations.

South African Fleet Management and Technology

- Cartrack South Africa: Industry Leaders in Fleet Management Systems (2025) — Overview of AI-powered fleet management capabilities including driver behaviour monitoring, AI cameras, and telematics solutions available in South African market.

- MiX by Powerfleet Africa: Transport & Logistics Solutions — Details on MiX Vision AI dashcams and fleet management technology deployed across South African transport operations.

- Webfleet South Africa: Logistics and Transport Software — Information on Fleet Advisor generative AI capabilities and transport management solutions for South African fleets.

WhatsApp Business Integration

- Clickatell: WhatsApp Business API Implementation — South African company offering messaging platform integration with case studies including FlySafair implementation, noting WhatsApp is used by 96% of South Africa’s population.

- DoubleTick: Top 10 WhatsApp Business API Providers in South Africa (2024) — Overview of WhatsApp Business API solutions available in South Africa including Clickatell, 360dialog, Cellfind, and pricing structures.

- SME South Africa: API Integrations for WhatsApp Store (2025) — Analysis of how South African SMEs leverage WhatsApp integrations for customer communication, order management, and business operations.

Process Documentation and Business Process Management

- Bizagi: Process Modeling Software — Free BPMN 2.0 process modelling tool enabling organisations to create and document business processes with export capabilities to multiple formats.

- Camunda: Free BPMN 2.0 Tool — Open-source process modelling platform with collaboration features and integration capabilities for process documentation.

- Miro: BPMN Tools — Collaborative diagramming platform for process mapping with integration to project management tools.

- Creately: Free BPMN Online — Browser-based BPMN diagram creation tool with templates and real-time collaboration features.

LLM Industry Analysis

- Sebastian Raschka: The State of LLMs 2025 — Comprehensive technical analysis of LLM developments including reasoning models, open-weight alternatives, and practical deployment considerations.

- Simon Willison: 2025 – The Year in LLMs — Industry practitioner analysis of LLM developments including agent capabilities, coding applications, and practical deployment patterns.

- Turing: Top LLM Trends 2025 — Market analysis of LLM adoption patterns, efficiency improvements, and enterprise deployment considerations.

Related ColdChainSA Content

- AI in Cold Chain Logistics: Separating Substance from Sales Pitch — Companion article providing framework for evaluating AI vendor claims including the three essential questions: Where does training data come from? What decisions does it actually make? Can you demonstrate improvement over time?

- Cold Chain Glossary — Comprehensive definitions of cold chain terminology including technology and monitoring terms.

- Temperature Monitoring and Technology Directory — ColdChainSA directory of monitoring system providers, data logger suppliers, and cold chain management software vendors serving the South African market.

About ColdChainSA

ColdChainSA.com is South Africa’s dedicated cold chain industry directory and resource platform. Founded by operators with over eight years of experience in temperature-controlled logistics, we provide industry intelligence, supplier connections, and technical resources serving South Africa’s cold chain ecosystem.

Our perspective comes from operating The Frozen Food Courier—dealing with the same challenges of informal communication channels, tacit knowledge management, and technology evaluation that every operator faces. We write from experience, not theory.

For technology providers offering monitoring solutions, workflow tools, or communication platforms for cold chain applications, directory listing information is available at coldchainsa.com.